One of the benefits of G-code is that you can string multiple commands on top of each other to create more complex designs. Home position is represented by the # sign (e.g., X#, Y#, Z#).

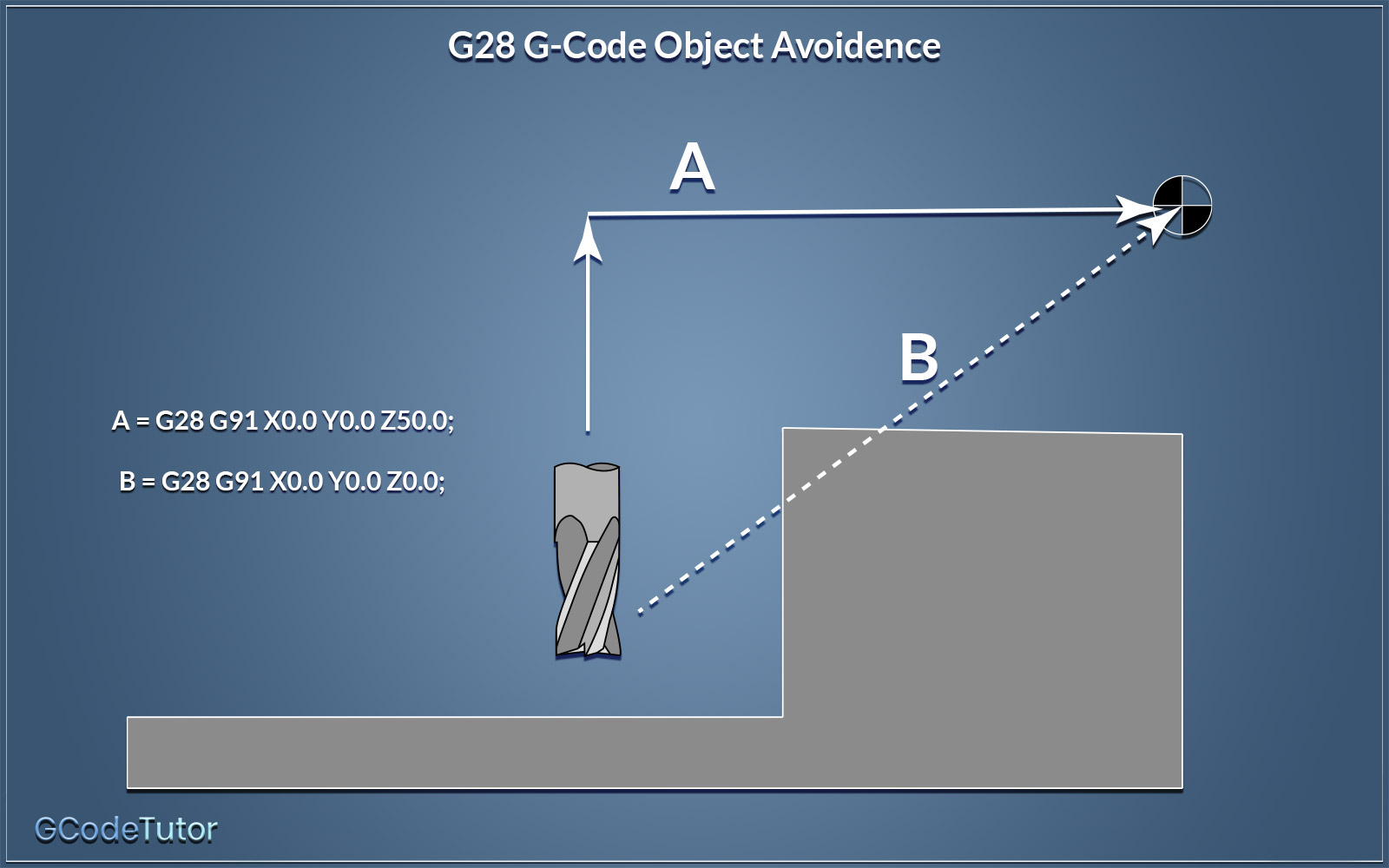

If that is the case, you can add an intermediate point so that the head avoids damaging your piece. However, while you’re working, you may create potential collision points. G28 codes indicate that the head should go back to zero. Once the machine finishes working, you need it to return to its starting position.

G CODE ZERO AXIS HOW TO

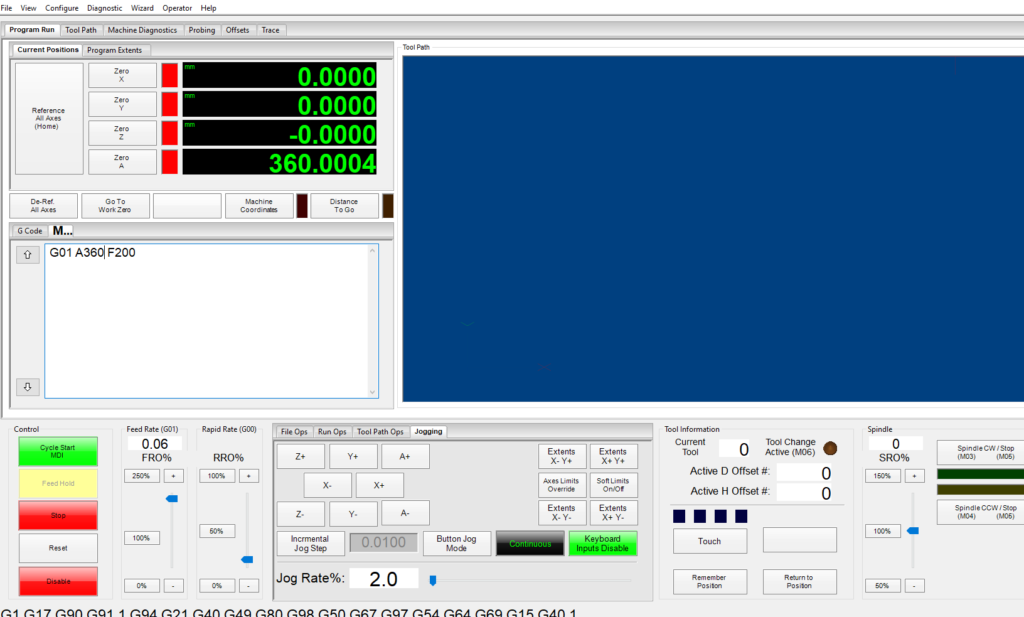

Learning how to input G-code takes a while to master, but it’s not as complicated as it may seem at first. However, understanding each element individually can help you maximize your CNC machining capabilities. You can use coordinates on all three planes to work in a three-dimensional space.Īs you can imagine, bundling all the different G-codes can create relatively complex programs. G18 is the XZ plane, and G19 is the YZ plane. G17 is the XY plane (aka a flat surface). The G-code you use tells the machine in which plane to work. While you’re working, you can cut in one of three planes – XY, XZ, and YZ. You still have to use I and J values to set the center point and affect the shape of the curve. G03 works the same way as G02, except the movement is counterclockwise instead of clockwise. Adjusting these values can widen or narrow the curve. So, if you input I6 and J-7, that means six points away from the X-axis and seven points down from the starting point on the Y-axis. Rather than putting coordinates in for I and J, their values are relative to the starting point of the command. These values will indicate the apex of the curve, thus telling the machine how to move. To help the machine understand the shape of the curve, you need to input I and J values. G02 codes transcribe clockwise circular movement. Straight lines are helpful for many pieces, but the beauty of CNC machining is that you can create any shape you like. Measurements with G21 codes are millimeters per minute. One element to point out with linear movement is that measurements with a G20 code translate to inches per minute. You also have to input the cutting speed, represented by the letter F. As with G00, you have to put the final coordinates in – then the machine will cut along that line until it reaches its stopping point. G01 – Linear MovementĪlthough this code translates to linear movement like G00, the machine is actually cutting and shaping. No cutting is involved with the G00 movement – it’s only designed to get the head from one point to the next. The program will locate these coordinates and move the cutting head in a straight line to that point. When entering this movement, you need to provide the axis points as well. G00 codes tell the equipment to move to a specific point on the X and Y axes. G00 – Rapid Positioningīefore you can start cutting or shaping your material, the machine needs to be in the right spot. Let’s look at some of the most common G-code commands you’ll find in CNC machining. However, since the code only tells the machine how to move (not precisely where), this limitation is not a problem. Examples of G-Code in CNC MachiningĪs you might have guessed, there are only 99 possibilities for G-code commands since there are only two numerals after the G.

Instead of cutting material, the machine adds layer upon layer. This section is followed by coordinates on the X, Y, and sometimes Z-axis (if your equipment can move on those axes). The way it works is that each line starts with a G number, such as G00. This programming language is designed to be simple and straightforward, although it’s not always efficient (more on that later). G-code stands for “geometric code,” and it tells the machine how to move.

0 kommentar(er)

0 kommentar(er)